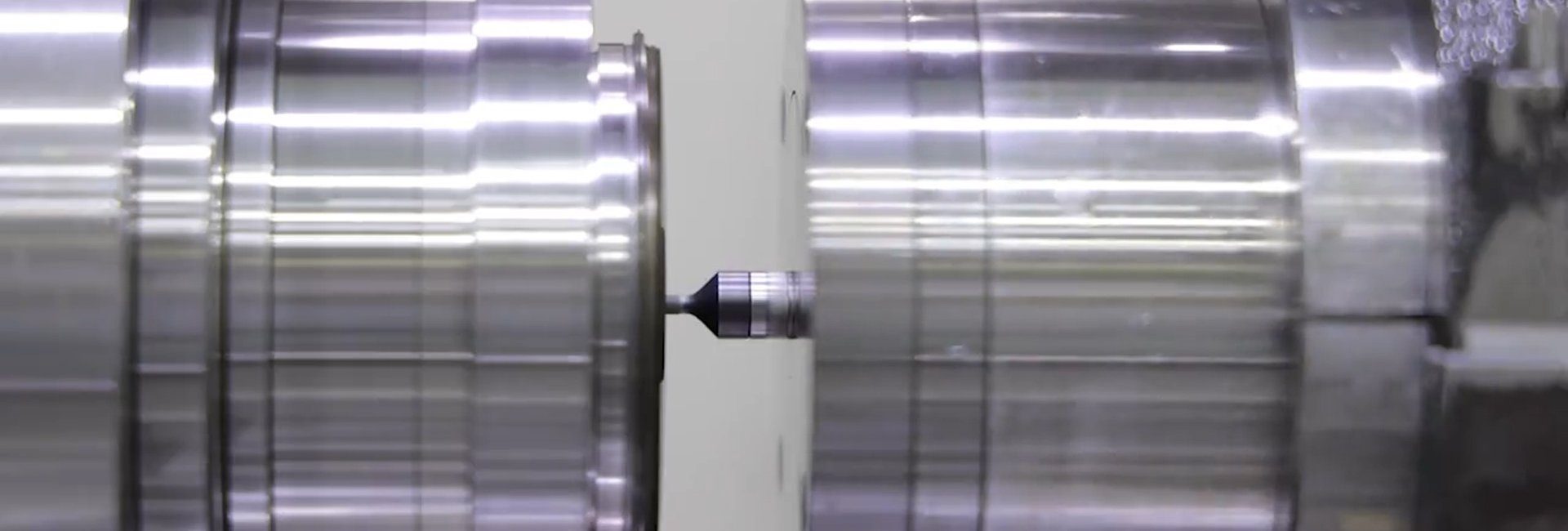

It is said that cars are made up of about 30,000 parts. In particular, parts used in engines, injectors, steering, and transmissions, which are aggregates of rotating bodies, require extreme precision. Our grinding machines have an extensive track record of delivering optimal processes for a wide variety of parts such as pistons, valves, injector bodies, nozzle needles, and plungers. In particular, for eccentric workpieces such as balance shafts, we propose a model that uses an inclined bed – one of our strengths – to meet high-precision requirements and production efficiency.

In recent years, along with the electrification of automobiles, we have started offering grinders for processing motor shafts, as well as centerless grinders for mass production screw groove grinding that responds to screw processing for drive actuators used in motors.