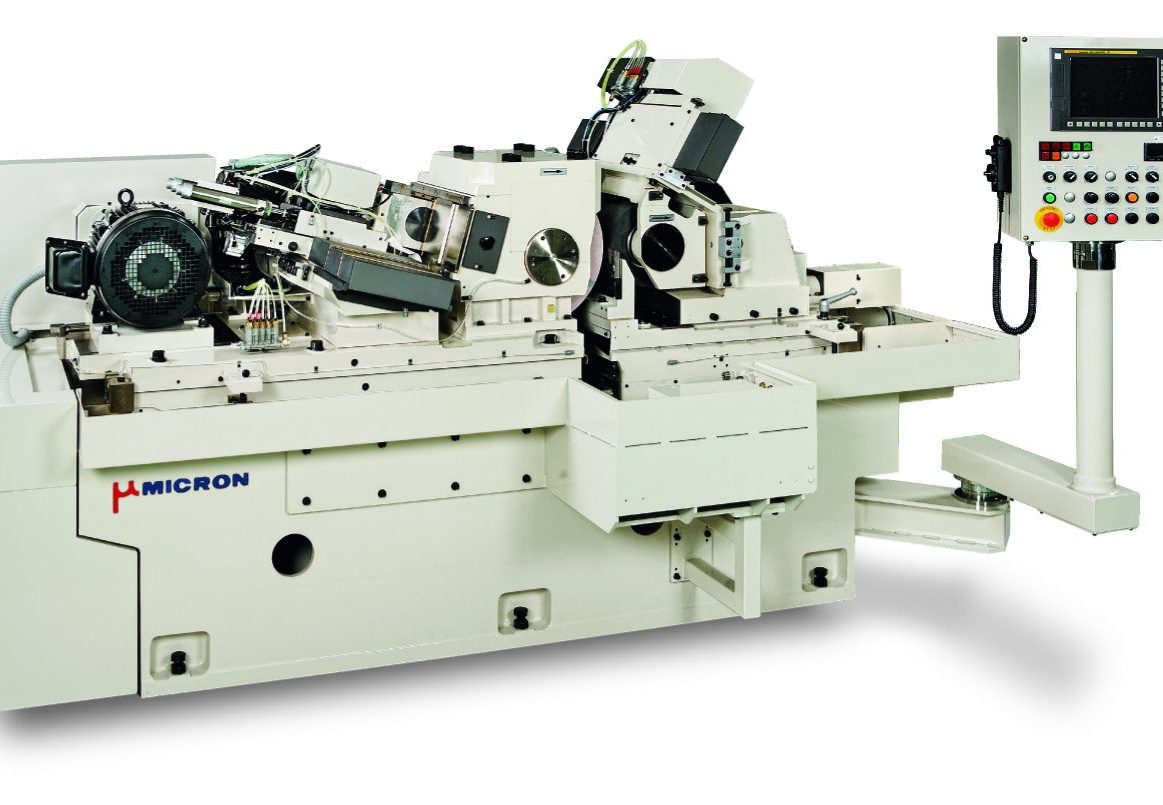

About Our Grinders

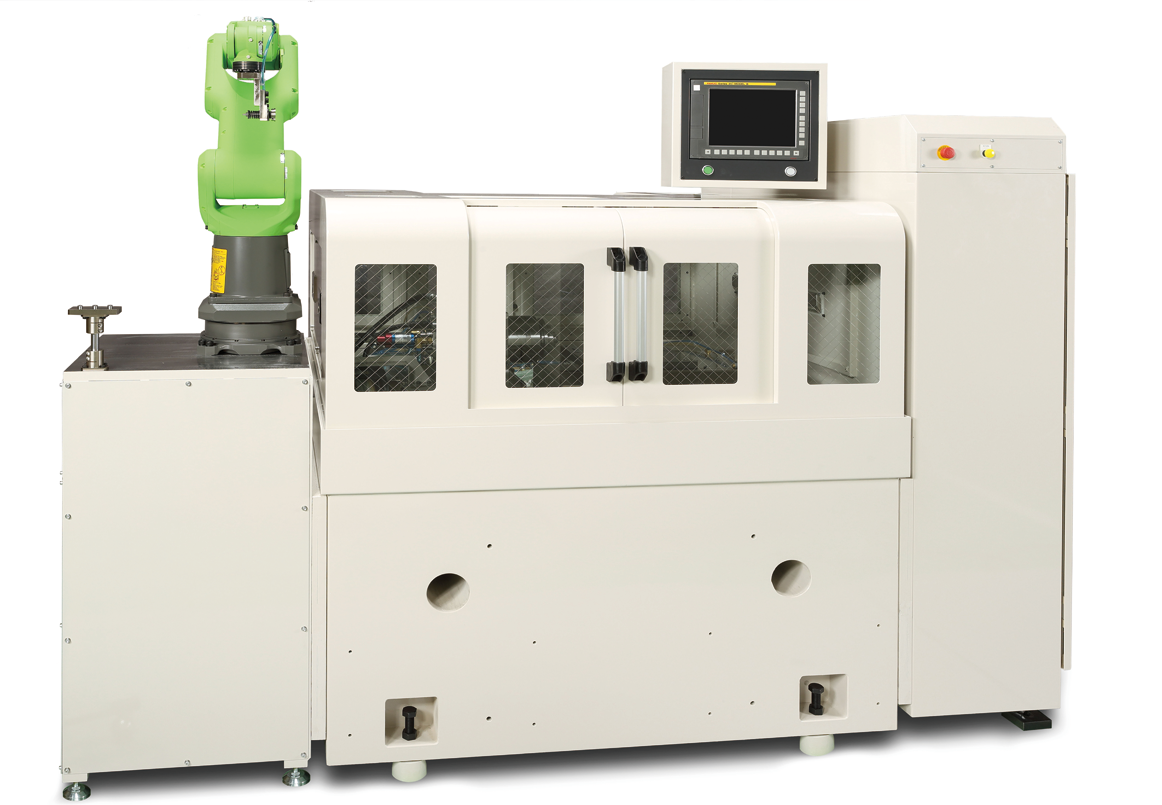

Micron built its first machine in 1959. Since then we have built over 7,000 machines with a relentless commitment to providing the best possible precision grinding solutions. Our goal has been to improve quality and productivity by applying state of the art, leading edge centerless and internal grinding technologies with our general use centerless machines, angular approach centerless machines, super abrasive centerless machines, specialty centerless machines, and internal grinding machines.

Micron’s mission with all of our precision grinding machine models is to continually improve roundness, straightness, and size on cylindrical parts to meet whatever our customers require now and in the future. To do this, Micron believes that processes and equipment must continually improve. No grinding paradigms can be allowed to influence the design of new equipment and Micron is determined to push technology to a new plateau to meet the opportunities that exist today and throughout the 21st century.